Digimarc Corporation has entered the next phase of the Digital Watermarks Initiative, HolyGrail 2.0, the company announced Sept. 7. AIM, the European Brands Association, and the Alliance to End Plastic Waste—the drivers behind HolyGrail 2.0—have joined forces with the City of Copenhagen to start semi-industrial trials in the next phase of testing digital watermarks for intelligent sorting of plastic packaging.

This milestone marks the second year of the HolyGrail 2.0 project, which includes over 130 companies and organizations across the packaging value chain. The project grew out of HolyGrail 1.0, a three-year initiative of the Ellen MacArthur Foundation’s New Plastic Economy to investigate innovations to improve post-consumer recycling (PCR). At the end of the study, digital watermarking was identified as the preferred approach over chemical tracers. “Digimarc’s solution provides virtually unlimited data on objects and provides brands with game-changing capabilities through digital transformation and consumer engagement,” says Mignon Senuta, Digimarc’s vice president ESG Engagement & Corporate Communications.

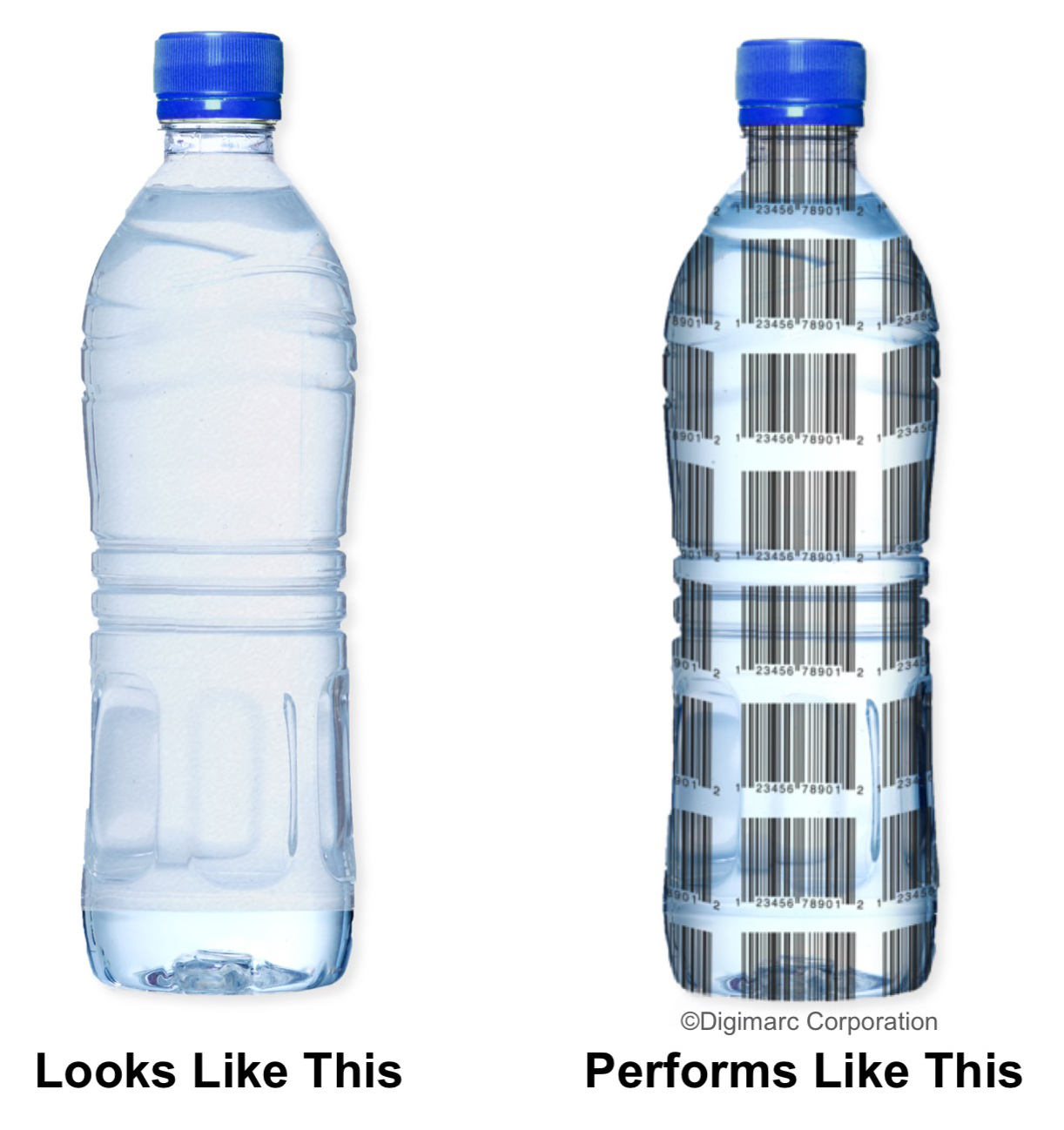

About the size of a postage stamp and imperceptible to people in everyday usage, Digimarc’s technology can cover the entire surface of packaging and be embedded in molds for 3D objects. Computers with cameras, such as smartphones, point-of-sale retail systems, and sortation cameras, can detect and decode the digital watermark when the packaging is collected and scanned. Packaging can be further sorted based on various attributes such as manufacturer, product, polymer type, and whether the plastic was previously used for food. For example, polypropylene can be sorted based on whether it was previously used for a toothpaste tube versus a do-it-yourself caulking tube.

“We like to say that digital watermarking gives objects a ‘Digital Recycling Passport,’” Senuta notes. “Recycling facilities using digital watermarks can elect to positively or negatively sort objects by leveraging characteristics in the data linked to the object through the watermark. This creates greater efficiency and efficacy in sortation, and enables the facility to optimize sortation based on desired fractions and market conditions. Importantly, the data attributes of objects can also be easily updated at any time, so that detections yield the latest and most accurate information associated with the object.”

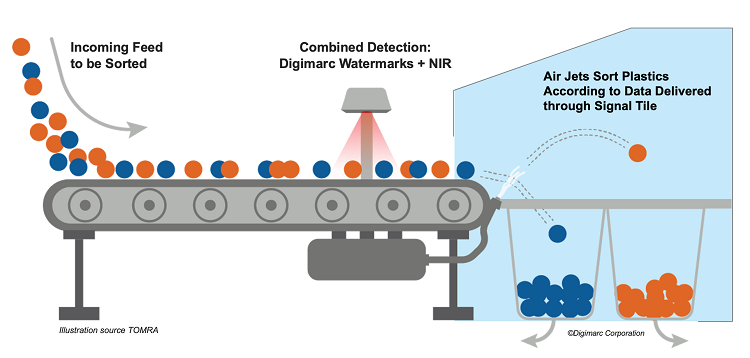

For the semi-industrial trials, Digimarc is working with machine vendors Pellenc ST and TOMRA to develop an add-on module for their detection sorting units, and will combine them with existing near infrared (NIR) sorters. Both vendors were members of the HolyGrail 1.0 initiative. “TOMRA created a proof-of-concept watermark detection module used in HolyGrail 1.0,” Senuta says. “The company held two highly attended industry demonstrations in 2019 at its corporate headquarters and R&D facility in Mülheim Kärlich, Germany.”

Having completed its phase 1 validation to combine digital watermark technology and NIR/VIS infrared sortation to achieve greater than 95% detection rate, Pellenc’s module is scheduled for tests in October 2021 at Amager Resource Centre (ARC) sorting center in Copenhagen. TOMRA’s detection module will undergo semi-industrial testing at another test location.

The tests will include 125,000 pieces of packaging from 260 SKUs (stock keeping units), from large brands and retailers. “During semi-industrial tests, packaging items will be manipulated to incorporate impacts of soiling, crushing, humidity, etc., to simulate conditions that are present in industrial-scale sorting and recycling plants,” Senuta explains. The sorting and detection system will be tested for accuracy, efficiency, and speed.

If the trials are successful, the next step is to launch in-market demonstrations and industrial-scale trials. Digitally watermarked products may be added to stores in Denmark, France, and Germany by the first half of 2022. “Industrial-scale tests will kick off with detection modules placed in multiple locations in France and Germany, including material recovery facilities (MRFs), plastics recovery facilities (PRFs), and other recovery facilities,” Senuta says. “During these industrial-scale tests, consumers will buy products with Digimarc watermarked packaging, and post-consumer-use packaging will enter the recycling stream to be detected and sorted by the detection modules at facilities.”

The HolyGrail initiative envisions consumers will support collection by scanning packaging material with their smart phones to learn how to properly dispose the materials. “Digital watermarking helps reinforce ISRI’s position in support of private sector recycling infrastructure and its goal of generating high quality raw-material feedstock in lieu of virgin materials in the manufacture of new products,” Senuta notes.

As these developments are underway in Europe, the company is turning its attention to North America. “Digimarc is currently in exploratory efforts with several organizations on implementing similar demonstrations and trials and is pleased with inquiries coming from the recycling industry and its trade associations,” Senuta says.

Featured image courtesy of Digimarc. Body image: Illustration Source: TOMRA, Courtesy of Digimarc.

Additional Resources